Auspex Water Troubleshooting

The Auspex Crimp System made for both cold and hot water applications, has revolutionised pipe fitting with its cut, fit, crimp, done process.

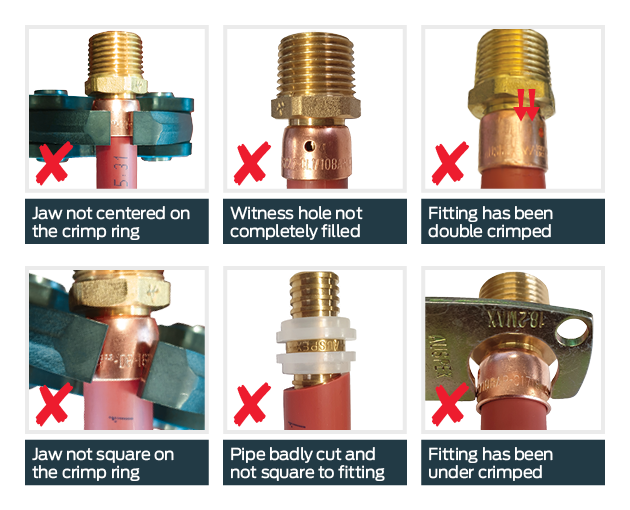

Ineffective Joints

The Auspex crimp system is simple and effective when executed in accordance with the jointing procedures in this manual. However, if sufficient care is not taken, this can result in an ineffective joint.

Ineffective joints may occur if:

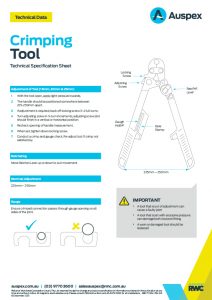

- The crimping tool has not been completely closed

- The crimping tool is out of adjustment. Re-adjust tool in accordance with the instructions supplied with the tool, and in this manual

- The copper ring has moved away from the fitting body

- The crimping tool has not been centred over the copper ring and the jaw has overhung the end of the fitting

- The crimping tool has not been at 90° to the joint being made

- The pipe has been cut badly out of square

- The witness hole is not completely filled (the fitting is not fully inserted in the pipe)

- The fitting has been double crimped

If an ineffective joint is detected:

- Cut out the defective joint and replace with new fitting

Non-compliant fittings that are removed cannot be re-used.

Examples of ineffective joints: